We often take for granted those little white and black keys. They set our melodic passages to motion within the piano as our fingers skillfully glide across them. Truly, if they have a good feel, they will fit leather gloves to our hands as well. If they have broken or sharp edges and sideward movement, it is unpleasant and lends inconsistency to our musical experience.

We will begin the discussion with several aspects of these keys that give us a good or not-so-good feel to our instrument. The keys are generally made of high-quality lightweight wood that has a center pin pivot point and a front pin under the approximate placement of our touch point that maintains consistent alignment. The two key pins (center and front) glide through their key mortises with high-density wool felt carefully lined inside the keys to give them a minimum of side movement and a smooth feel.

On the opposite side of the key's playing surface, you will find the capstan. (The grand keys also include the back-check, which catches the hammer just after it strikes the string.) In the picture above, you will notice that the brass capstans are polished with brass cleaner and then lubricated to reduce any friction caused by metal oxidation. Likewise, in the lower picture, notice that the key pins are also cleaned and lubricated. This is part of the maintenance program I call "friction point service." This greatly enhances the ability to have a very responsive key, and that aids in the dynamic expression and repetition speed of our piano!

Following issues, we will see the process of "red bushing" the key mortises and restoring the new feel from the worn key-bushing felt that gives us a loose/sloppy key movement. Today, let us examine the keytop surfaces and what can be done to restore their feel and appearance. Of course, our present and end piano values must be considered before entering into this investment. This may increase a quality piano's value but may exceed the reasonable investment value of low-end pianos. There is always someone to take your money! The keys below require a few ivory replacements. The ivory must be matched for color, thickness, length, and width. This is not just a process of taking old ivory off one used key and placing it on another!

The above ivory and ebony keys have been "restored" with color matches and then polished. This is a premium to have the "Good Stuff." This comes at a high price, and plastic replacements may be more economical if there were several to replace. Below is a plastic keytop replacement that simulates the ivory color in an alternative to "bright plastic white." This is my preference for older pianos to enhance the original appearance when the original keytops are not an option.

An alternative to a low-value piano may be to simply file off the rough-end edges (see below). This allows you to have the ivory feel still and significantly reduces the cost of a complete keytop replacement.

The next picture shows the process of replacing the new keytop. This is a very exacting process to maintain key squareness, consistent key thickness, and proper adhesion and finished edges.

Notice the new red key bushings (center) have also been replaced. Many times, piano keytops have been replaced without replacing the worn key bushings. I believe that is like repainting a nice car without repairing the body underneath the new paint. The result is not only to "look good," but most importantly, it is the TOTAL FEEL that a finished job results in!

After the keys have the keytop surface restored or replaced...the key dip and the keys need to be leveled. This includes white and black keys.

Hopefully, this topic on keys may help you appreciate the significance of how they not only look but especially the feel of them. Several of you have emailed with questions on specific considerations for your pianos. We are always glad to hear from you. We may not be able to service your piano in a distant location, but we always enjoy helping you through those important decisions for your piano.

There are many skilled piano technicians all over the world! I hope that in the next few months, these technicians may help you appreciate their devotion and love to the art of restoration of quality instruments. A first-class restoration adds value and years of pleasure to your musical experience.

Key Issues

In the previous issue, you might have noticed that occasionally, the keys are in good condition, and yet the key bushings are being replaced. The quality and tolerances of some piano manufacturers become evident after a few years of use. Sometimes, the piano may have many things in good condition, and yet, the quality of felt used in the key bushings becomes obvious.

When the time comes to rebut the keys, the cost of the highest-quality bushing felt compared to moderate bushing felt is a small price difference compared to the labor and the skill of your technician. I do not want to promote a certain brand of piano over another, but I have rebuilt high-end pianos that have over 60 years of service where the key bushings were in better condition than lesser-quality pianos with less than ten years of use. Some of the prices reflect long-term costs in maintenance, tuning stability, and resale values. I would highly recommend reading "The Piano Book," written by Larry Fine, where he addresses these piano grades.

After the key bushings, the key surfaces (keytops), and the center pin holes are restored to good condition, the next attention concerning the actual keys must be toward the key pins, capstans, and the keyframe that the keys rock upon. If mice have roamed wildly in this piano, their urine has probably ruined the center pins.

Polishing or sometimes complete replacement must be considered. This relationship of key fit and making a frictionless movement has everything to do with the success of speed of repetition and level of dynamic control or the lack thereof. Without a good fit of keys and keyframes, it is impossible to refine the "regulation." (Regulation is the relationship by timing of the mechanics within the piano action that transfers fine touch movement into musical tone and expression.)

This concludes our series of "KEY ISSUES." I hope it has given you some new appreciation of these little white and black keys that if in the correct order, make our efforts a pleasant musical experience!

I always look forward to your email and correspondence regarding these articles.

Several of you have contacted us concerning the possibility of replacing your instrument with a new keytop. My reply to your consideration of this in your piano was:

"What is the current value and condition of your piano, and what will the end value of your piano be after this considerable investment is completed?"

Many will take your money with no consideration, such as, "Was this a wise investment of your dollar?" Yes, many worthy instruments will greatly improve the piano's end value, but equally, more instruments could use this service, but the cost may be more than the actual value of the "fair market value" of that instrument.

The piano pictured above would fit in the group that key repairs, if significant, may not justify the investment (in my opinion). The waterfall keys are very interesting but are outrageously expensive to repair/replace. These types of keys were almost entirely in spinets and consoles, and the present age now has other aging areas that require attention. I don't know of any moderate- or high-value pianos with this-style keys that would justify the cost of new keytops of this style. By making that statement, if there are some, I will hear from someone, and I shall stand corrected and report this to you! Until then, I will keep this statement.

You may have noticed in the pictures that by the time I am replacing the finished keytops, the key bushings have been replaced. This is for good reason. The key bushings, if found to need replacing, will be steamed out, and the mortises and balance hole resized with steaming as well. With all this attention and steaming process, the risk of damaging any keytop surface must be considered, saving it for last. Many times, it may have been the keytop that was the first reason to begin this process.

Let us first examine the condition of the key bushings to evaluate the need.

The above center key bushings are not only very worn and loose, but the glue has loosened to where the felt is missing from some bushings. (See the middle one.)

In the next picture, you may notice there may be broken key buttons that need repair as well.

These front key bushings have much damage from moths and/or silverfish. There have been many times that a set of keytops was replaced, and yet, for some reason unknown to me, the replacement of the worn/damaged bushings has not been done.

Key Brushing Removal

At the same process time, we will resize the balance holes by steaming these as well.

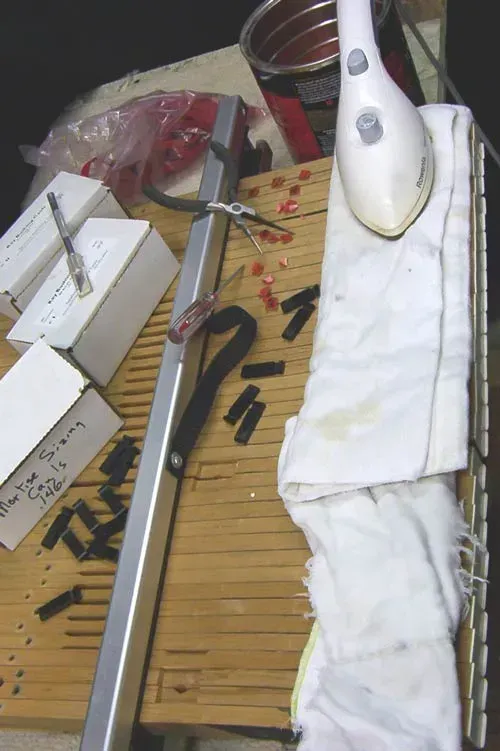

Immediately while the wood is still damp, the sizing calls are inserted into the mortises or pin holes. The keys are then allowed to slowly air dry for several days before proceeding. Below are the mortises after the sizing calls are removed.

Next, we must determine the correct bushing cloth so that the bushing is going to give a firm fit to the key pin with a minimum of side play. The original bushing cloth may have not provided a long service life if the manufacturer of the piano had used a lesser quality of bushing cloth. This is an especially noticeable difference with the lesser-priced pianos.

The process for re-bushing both front and center bushings is the same, only using the proper-sized calls for the pin for that mortise. The glue of preference for this, as with any future replaceable joints, would be to cook/make your fresh hide glue. The advantage of using hot hide glue is that it begins to bond as it cools, and more importantly, the glue can be steamed apart again in the future without damage to fragile wooden parts. Hide glue has been the preferred glue for many centuries in fine wooden musical instruments as well as fine furniture.

The above vertical piano keys have been re-bushed and are now ready to fit into the keyframe for pin sizing and leveling. The bushings will require adjustment for exact fitting.

When the keys are to be re-bushed, I feel that it would be better to err with an extremely high-density wool bushing cloth and endure a "break-in period' just as with a new piano. The result will be a longer, more durable bushing of much greater quality than some manufacturers' original bushings. It never fails; no matter how much I explain this, I always must remind the pianist of it a few months after the re-bushing process. The piano factories have a machine that works the keys, and action is felt thousands of times before final regulations are set for the piano. I don't have such a machine, but I strongly believe it is better to have tighter tolerances to start with than to fit with looser fittings that, after a few years, are not any better fittings than the worn parts we replaced in the first place!

I will carefully "iron" these new bushings to settle them, as well as polish the pins and treat the bushing cloth with Teflon. This does not mean that we are not going to have to still play in the fit! The wonderful end will be a nice solid feel with no side play.

Just like ironing anything...the temperature must not be too hot!

There is another process of just "easing the keys," which is crushing the side walls of the keys on each side of the new felt bushings in small increments. To some piano techs, this is a fast fix to sluggish tight-fitting bushings. I believe if the key mortises have been correctly sized and the felt fits properly with high-density felt, there will no longer be a solid substitute to avoid the temptation to "crush" the keys; instead, patiently iron and break in the fit.

Above are a few key tools used in this process: (1) Key-easing pliers, (2) Pin bender, and (3) Pin hole eraser tool (for the center key-balance hole as well as bushings). As I explained, I'm not very fond of the first tool. It is because of the use of this tool that I steam the mortises back to dimension and repair the previous damage of key compression before re-bushing with new cloth. (But then, that is in my humble opinion.)

For all your questions, call us today at (816) 260-7651!